Cangzhou Metalign Machinery Co., Ltd.

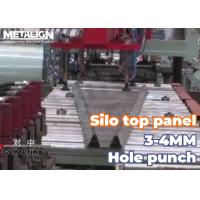

Metalign is a trusted manufacturer specializing in cold roll

forming machine production and custom roll forming solutions.

Located in Botou City, the heart of China’s roll forming industry,

we bring over 30 years of combined technical and engineering

experience to every project.

Our team is dedicated to designing and building precision roll

forming lines tailored to your profile needs — from roofing and

purlin lines to shelving, door frames, highway guardrails, and

more. We are known for our practical designs, robust structures,

and responsive after-sales support.

With a strong reputation in global markets including North America,

Europe, Southeast Asia, and the Middle East, Metalign is committed

to helping customers improve efficiency, reduce costs, and gain a

competitive edge.